During the early part of 2017, TimberHomes designed and cut a timber frame for a sunroom in Southampton, Massachusetts. The homeowner, Steve Silverman, owns a business in a peer-business group that TimberHomes is a part of, called Building Energy Bottom Lines (BEBL). BEBL is a part of the Northeast Sustainable Energy Association (NESEA) and as such, has committed to the triple bottom line of People, Planet and Profit. As the owner of Valley Home Improvement, Steve is a valued partner to our business, and it was a true pleasure to make a meaningful contribution to his home.

The project was particularly enjoyable because it represented a sizable amount of timber frame scribe work. Spanning the width of the sunroom are two immense 24′ curved Hemlock tie beams that were harvested from TimberHomes owner Josh Jackson’s land and milled completely by hand. In this case, the ties’ natural curves were left in tact, and the extent of the milling was to “flatten” the front and back of the logs. Doing so revealed their heartwood centers, but also left their tops and bottom still “in the round”. Each tie beam rests on a pair of tree forks, which were simply peeled and left completely round. Using careful layout techniques and custom-made bubble scribes, TimberHomes joined the forks to the ties with full mortise and tenon joinery, secured with White Ash pegs.

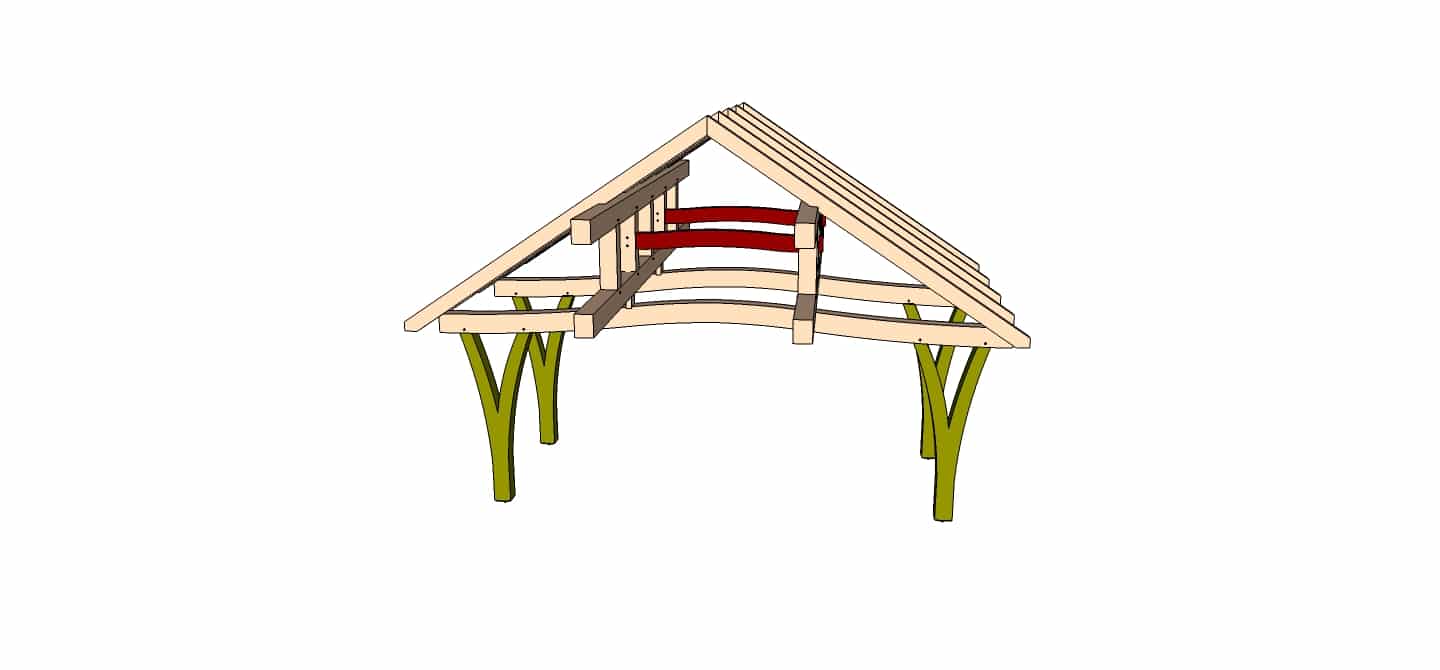

Above the Hemlock ties, there are a pair of purlin trusses consisting of a lower chord, an upper chord, and five short 8×8 posts. The purlin assemblies are joined to one another with a pair of curved Cherry tie beams, which were “flattened,” similar to the Hemlock Ties, to reveal their colorful heartwood. The purlin trusses sit on short posts, that have stub tenons joining them to the Hemlock tie beams. On top of the purlin trusses, there is a series of heavy timber rafters carrying the roof.

This sunroom is a hybrid structure, and as such, the sunroom’s exterior walls are stick framed. This work had been done prior to the raising by the Valley Home Improvement’s crew, and the walls stood ready for the installation of TimberHomes’ structure. A local crane operator was hired to assist with the process.

Having been put together prior to transport, the fork and tie beam assemblies were first in the raising process to be flown in by the crane to their predetermined location inside the stick framed outer walls. This done, they were temporarily secured. Next, the purlin assembly, also having been joined prior to transport, was then lifted as a single unit to its final resting spot on top of the tie beams, and secured on its ends to the stick frame. Finally, the rafters were flown up one-by-one and screwed down.

The whole timber frame raising lasted a single (long!) days. It was quite satisfying and went together smoothly. The timbers fit together well and they joined the outer walls just as planned. Owner, Steve Silverman was also quite happy with the end result. Summing it up, he added, “The frame TimberHomes designed and raised for my new home is beyond my expectations. It is well crafted and elegant. Josh and Timo have been fantastic to work with, from design through raising, and watching the crew erect the frame was like watching a well choreographed dance. I would recommend them to anyone considering a timber frame structure.”