Winter is the time for turning inward, for coming in from the cold and asking, “what can I improve in here”. While this metaphor lends itself quite easily to the quietude and reflection many find within themselves during the cold winter months, it also applies to more practical matters. At TimberHomes Vermont, winter is our time for shop improvement projects and overhead work. After a long season of building, shop work in the snowy season can offer a chance to accomplish the improvement projects that keep our two shops in happy working order.

This January in our Montpelier shop, work is underway on a project many have been looking (or perhaps listening) forward to for years. In our spacious, open timber frame shop, with its soaring ceilings and concrete floor, the pop of nail guns and reverberating buzz of power tools often makes for an echoey, at-times-overwhelming soundscape. Many timbergnomes have experienced difficulty in hearing each other speak at a normal volume in an effect that can only be described as, “so loud you can’t hear anything”. The solution to this chaotic auditory plight is a cleverly designed system of sound dampening panels, masterfully designed by TimberHomes’ own Andrew, that will absorb a portion of the sound and echo in the shop, making it easier to make out what others are saying and lessening the piercing noise of power tools.

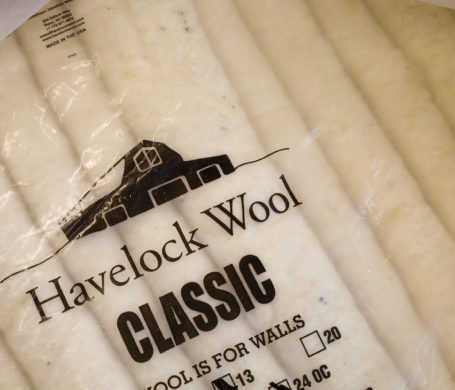

In total, the Montpelier crew will assemble and install over 300 of these 2×2 ft. panels. Their construction is simple: A square frame of rough sawn 2×3 pine, filled with natural wool insulation and wrapped with a special fabric engineered for exactly this purpose. Perhaps counterintuitively, the outer layer of fabric absorbs no sound at all, but rather lets all sound pass through so it can be absorbed by the wool within. And yes, these panels are filled with natural sheep wool. Can ewe believe it? 😉

Each panel gets four eye hooks, and then they are ready to be hung on the walls and ceiling. Using laser levels and a grid of chalk lines on the shop floor, the position of each set of wall hooks is determined. Drywall anchors coupled with protruding L hooks ensure that these panels are held off the wall about an inch and a half, dramatically increasing their effectiveness. After much deliberation by a specially appointed committee (aka anyone who has strong opinions about color pallettes aka just about all of us), two fabric colors were chosen to compliment the wall and ceiling paint colors.

Our ears will tell us just how effective this shop upgrade is. At the time of writing about a quarter of the sound dampening panels are hung, and some folks report being able to notice a subtle difference in the quality of sound in the shop already. Ideally, we won’t need fancy instruments or finely tuned microphones to hear the difference. It ought to be obvious in the way that the familiar sounds of the tools we use everyday hurt our ears a little (or a lot) less. And who knows, we might even be able to have a group conversation in the shop without everyone saying, “huh!?” all the time.

So, here’s to winter and doing the work within, whether that be returning from the job site to make our shop a more pleasant environment to work in, or doing some year-end reflective navel gazing, asking ourselves, “how can I make it a little quieter in here”.