The Montpelier Shop has been preparing for two months to raise a new barn in Montpelier, just up the road from the black barn we completed back in December. Unlike that barn, however, this structure includes an insulated studio apartment and workshop space within the larger structure. The back third of the barn, the insulated section, was cut in planed eastern white pine and cherry, and will be finished and insulated with rigid wood fiber insulation. The front section of the barn is cut in rough sawn timbers, and will be enclosed, but not insulated. An insulated wall separates these two sections of the building. Accordingly, the insulated section of the frame has to be raised and the adjoining wall built out and insulated before the rest of the frame can be connected to it. Thus, this raising is happening in two parts, with a week or so between them.

At the time of writing this, the crew has just raised the apartment section of the frame, and the ceiling has been paneled with whitewashed tongue-and-groove pine. Underlayment has been installed atop that, keeping any moisture from seeping onto this finished surface and protecting the timbers immediately below. Now, the principle task before the crane returns to site is to panel the adjoining (east) wall, install that same moisture barrier, rigid insulation, and wall strapping. Some of that wall strapping will be more structural, and act as posts on which the timbers for the barn section of the building will land.

Every timber over the slab was raised on the first crane day. The crew worked together in harmony to raise this frame in a whirlwind morning, and the crane was sent home by lunch. First, two lower bents were raised and attached to the slab foundation, the, their plates were attached, effectively joining the two bents into a single structure. After that, each lower bent received an upper bent, featuring beautiful cherry braces that will make a real statement inside the finished apartment. Once all bents and plates were in place, rafter sets were flown in and joined together at the peak of the building. It is often during this step that the crew begins to marvel as the structure takes shape. During rafter raising, Dawn and Molly will often look at each other and exclaim, “Can you believe we get to do this for a living!?”

With the crew well ahead of schedule on raising day, there was even time to accomplish some tasks which weren’t scheduled until the following morning, which was fortunate considering the rainy weather that came in. It all evens out in the end, and with the first part of the frame up and work underway to prepare for the second section, movement one of this two-part symphony comes to a melodious end.

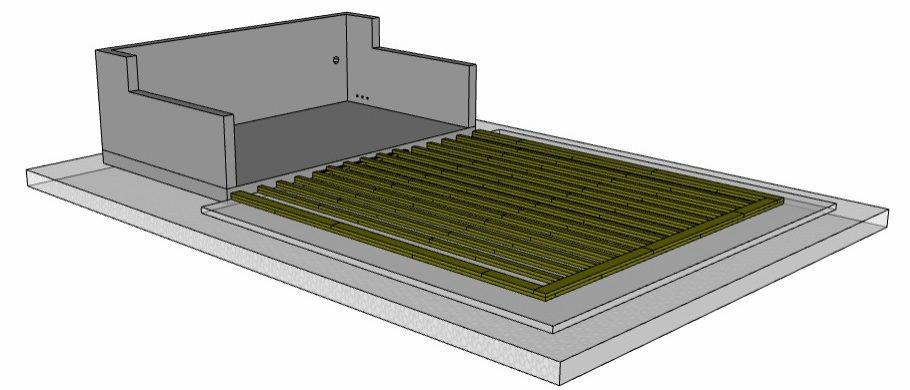

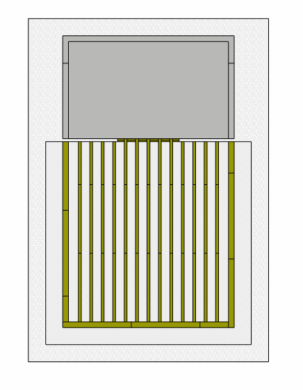

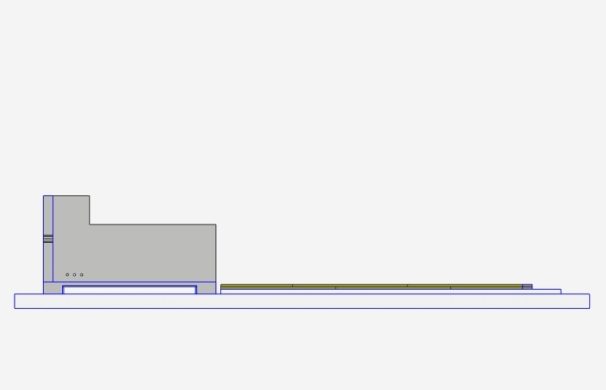

This building is truly a hybrid from the ground up. In addition to the structure being only partially insulated, and only some of the timbers planed, the foundation of this structure is also built in two parts. The apartment/workshop section is a concrete slab with frost walls on three sides, and it is set back into an embankment. The frost walls are insulated all the way to the base, the slab is plumbed for radiant floor heating, and the frost walls extend up as high as six feet in the rear (west). The apartment is on the second story, above the slab foundation, with stairs for access inside the uninsulated barn section.

The foundation for the barn portion of the frame, however, is a glavel (recycled glass gravel) pad with a vapor barrier, and locust sleepers supporting a hemlock floor deck. The ground beneath is sloped away with adequate drainage around the perimeter. These two foundation sections are joined by a hardwood sill bolted to the concrete slab, which the center section of sleepers are secured to. As with all foundations, laying this foundation out and getting it all to end up as a single level plane involved several days of surveying, shoveling and raking rock and being mindful of one’s steps as the sleeper section was being connected to the slab section.

Joining these two very distinct parts of the building involves attachment points every step of the way. The foundation is joined together as described, and the walls and roof will be structurally bonded with roof strapping, creating a three dimensional hold that will ensure this building stays together as one for many decades, perhaps centuries, to come.

Stay tuned for updated pictures on this post, showing the build-out on the adjoining wall, as well a subsequent post detailing the second movement of this beautiful barn raising symphony.