When timber framing a large structure, the problem will invariably arise how to get enough length out of your plates. Most traditional sawmills are not equipped to handle wood that is much over 30′, if even that! And even if you can find a mill willing to saw 40′-50′ logs, the other vexing problem is actually sourcing wood that is large enough to mill 8×10’s or 8×12’s. In both of these cases the small end, or “tip”, of the log would need to be at least 13″ and 15″ respectively. At an extremely long length, this would indeed be a hard nut to crack!

In the Northeast, trees tend to be shorter and knottier than in the West, While exceptionally long, girthy, and sound White Pine and Hemlock specimens can be found, they typically do not exist on every woodlot. And when located, their board foot prices tend to be prohibitive. For this reason, we at TimberHomes rarely spec anything longer than 20′-24′. In terms of consistent quality and availability, this is the “sweet spot” for our longer timbers.

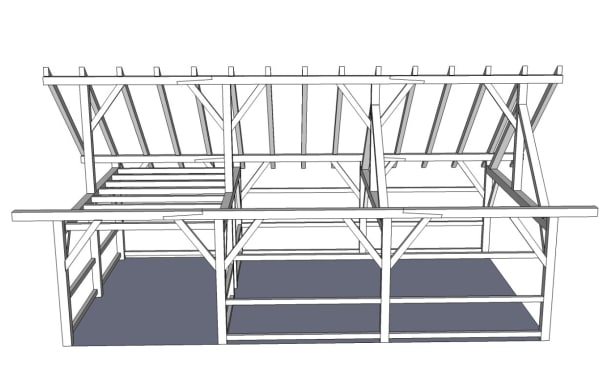

So then, how can you create buildings, or more specifically plates, that are 40′-60′ or even longer? For timber framers, scarf joints are the answer. On the end of two plates, a mirror imaged, angled half lap joint is cut. Typically about 3′ long and cut at approximately 66 degrees, the scarfs have mortice and tenon joints on each end. Two Ash or Oak pegs securely hold the two planes together. Often the top of a timber brace extending from an adjacent post is located at the bottom side of the scarf joint for additional support.

Unlike most timber frame joints, we do test fit scarf joints to ensure that they match nicely. In most cases, though, they are then taken apart and installed individually. After the first scarf is placed into position atop a timber post(s) and braces, the second scarf is “flown in” slightly tipped towards the joint. After the tenons begin to engage, the rest of the plate is lowered slowly. While keeping the joints of the scarf in tact, the other mortice and tenon joints (braces and posts) can be engaged one at a time until the entire plate is well coupled with all of the other timber members.