A Spacious Working Barn for Neighbors

Behold, a beautiful, functional locally sourced barn. We were delighted to raise and enclose this structure in 2022, for neighbors just up the road in Montpelier, VT. This three story barn is used for vehicle and equipment storage, and as a woodworking shop and creative space. In its free time, it hosts dance parties, and looks stunning, with it’s black stained exterior in strong contrast with creamy eastern white pine beams.

Monitor Barns offer Precious Light in a Northern Landscape

The design of the monitor barn, with its elevated central aisle, came about originally as a way to increase airflow through a building, helping keep bacteria at bay in the grain stored within, and air fresher for livestock. It has the added benefit of allowing more sunlight in. If you’ve driven to Burlington along Route I89, you’ve undoubtedly seen the impressive East and West Monitor barns, owned and maintained by the Vermont Youth Conservation Corps.

The clients for this Montpelier Monitor Barn came to us with a clear sense of what they were looking for – in our initial conversations, they described banking a monitor barn into their hillside. They wanted to take advantage of an open/walkout basement for equipment storage, and also have the barn reach high enough to gain access to the scant Vermont sunshine on their forested site. The main floor would need to be designed around parking a heavy tractor and a large truck. Their big picture goals for this building were laid out, and our job was to design the barn to meet these goals.

Designing a Functional Frame that Withstands the Tests of Time

Designing this barn to meet the clients goals offered some interesting design opportunities. The finished project had 900 square feet of usable basement space, and a 16’ x 36’ area in the top floor – the monitor area – as a workshop space. There is also a cantilevered steel track running the length of the monitor, and double doors to the outside, making it easy to haul materials to the upper story, which you can see in the photo at the top of this page.

The floor and roof loads in this building were large enough to warrant consultation with licensed engineers specializing in timber framing. With the help of Fire Tower Engineered Timber, we landed on some variations from our typical practices. To get the clearspans we wanted in the parking area, we used steel I-beams as the main carrying member in the first and second bents – a first for TimberHomes. The floor framing in this area was full 2×12 hemlock lumber, space 12″ on center.

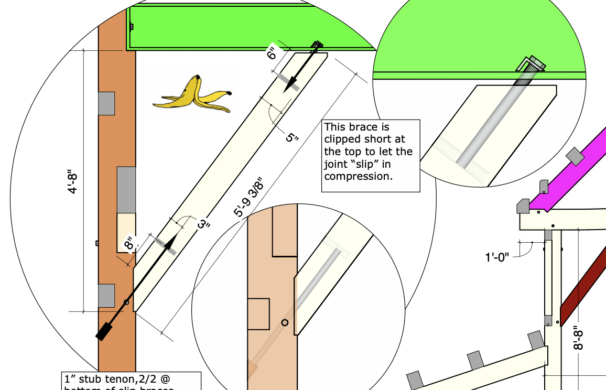

Perhaps the most interesting novelty was the use of a mechanical slip joint for the brace-to-beam connection in the second bent. There was some concern that the large roof and floor loads from the monitor would be transferred to the outside posts through the knee braces, an amount of thrust those posts and their connection to the foundation would not withstand. A knee brace’s only job in a timber frame building is to keep the building square as various loads try to rack it, but whether we want them to or not, braces will transfer loads when they are in compression. Braces always come in pairs, and as a building experiences load from wind, for example, one brace in a given section of the building is compressed, and the other is ‘stretched’, or in tension. Using a ‘slip’ joint prevents a brace from acting in compression, because it is allowed to ‘slip’ upward into the beam above it as the building racks. Thus, only the brace that’s in tension will be working to keep the building true.